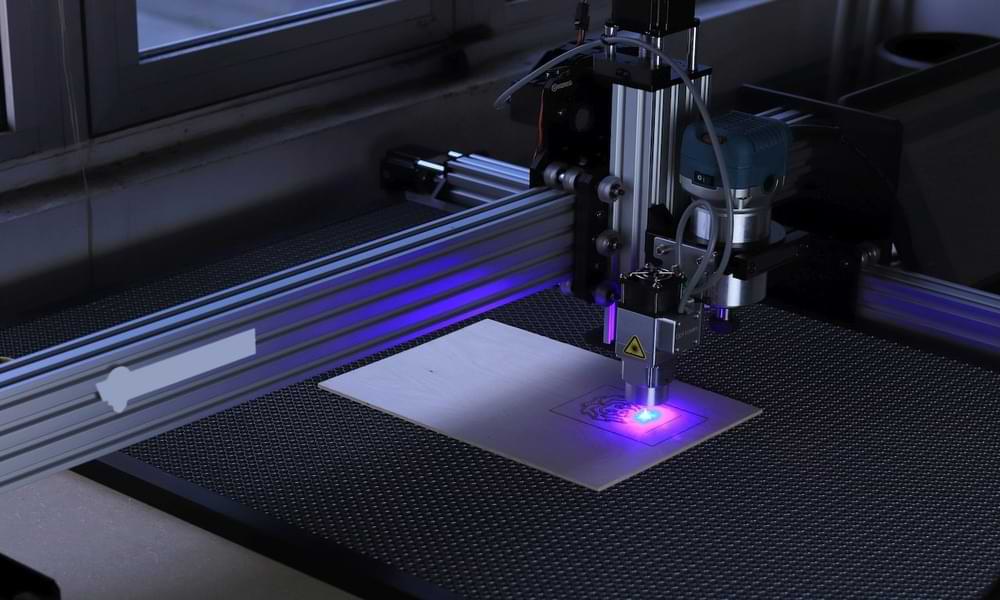

While a metal laser cutter can work wonders with a wide range of metals, there’s a lot to love about working with aluminium. In fact, we can think of 5 great reasons why the next metal you laser cut should be aluminium.

From the get-go, aluminium is a top choice of material for a wide range of industries and applications. Whether you’re working in the medical field, industrial area or just looking to create a unique artwork, laser cut aluminium can be an excellent solution. This is because the material is extremely lightweight, non-toxic (making it a strong contender for medical and food-based applications) and has a high thermal conductivity. The latter can be a necessity in some applications where great amounts of heat are generated and need to be dissipated quickly.

Along with being versatile, aluminium is also a strong material to use. It offers good durability, while it is also naturally resistant to rust and corrosion, as well as many chemicals. These properties can also be enhanced with additional coatings or films applied to the aluminium post-laser cutting.

Despite being a strong metal, aluminium has that rare combination of strength and high flexibility. This means it can be easily manipulated to create the shapes or forms that you require, such as cylinders, and then laser cut to achieve that final ideal result. And, any that does occur, can be easily recycled, making aluminium an environmentally friendly choice, as well as an efficient and effective one.

While some applications for laser cut material may not require an aesthetic or more than simply functional result, aluminium can also look quite striking once it is laser cut. This is because you can anondise aluminium once it has been cut, enabling you to colour it for a more dynamic final product. Similarly, you can complement laser cutting with laser engraving to get a highly detailed finish with a strong contrast. This makes engraving aluminium an alternative to printing on it for barcodes, labels and QR codes, for instance.

Whether you’re worried about supply and demand, or simply your manufacturing costs, you’ll be pleased to know that aluminium is an abundant material. Compared to other metals for laser cutting, it is quite cost effective, particularly when you factor in how versatile and durable it is.

It’s not a question of whether you can laser cut aluminium or not. However, this metal does require a bit more skill and precision than others. But given all the great advantages listed above, we think it’s still extremely well worth it.

Aluminium is a great metal to laser cut, however you need a competent and skilled operator to ensure you get the perfect end result. This is because burrs can form if the cutting parameters are wrong. Issues like the incorrect speed, too much or too little power, the wrong gas pressure, and the nozzle being an incorrect distance from the surface and focus point can all contribute to burrs.

As a result, more time may need to be spent removing the burrs post-cut. Of course, as the saying goes ‘measure twice, cut once’, you won’t have to worry about burrs if you choose an operator who knows what they’re doing, like the team at Lightning Laser.

Working with a more skilled operator who can flawlessly cut aluminium may make the initial laser cutting price go up a tad, but it is well worth it. For instance, you can trust that you’re going to get the result you’re after, including no burrs. Therefore, it’s important to remember that the cutting stage is just one stage of the end product’s overall life. Given the great advantages this metal has in a host of industries and applications, and its relative cheapness to purchase, many people find that these costs balance out in the long run.

If aluminium sounds like your ideal metal to work with, Lightning Laser is here to help! Our experienced laser cutter technicians and advanced technology can get you impressive results using aluminium. So, be sure to talk to us today to learn more.