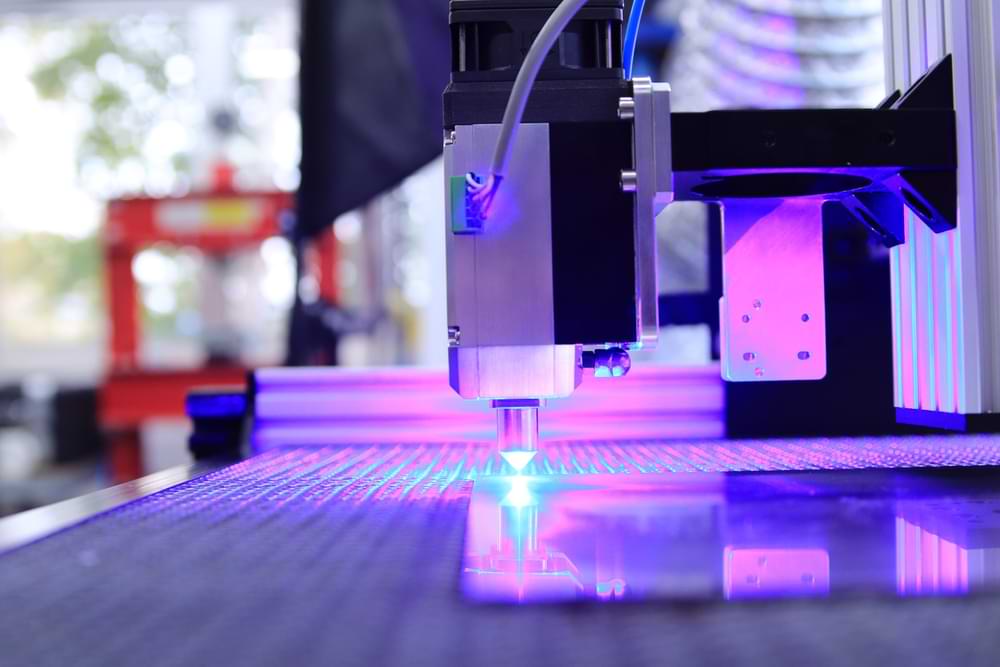

Today, we’re diving deep into the world of laser cutting machines for engineering and construction with the experts at Lightning Laser. Buckle up for a ride through capabilities, execution secrets, and some optimisation magic to solve problems and build solutions like a pro.

Let’s start with the good stuff. These machines are the ninjas of precision, slicing through materials with jaw-dropping accuracy. Think of them as your crafting sidekick, armed with the power to conquer various materials, from metals to plastics, like it’s a walk in the park.

Pinpoint Precision: Laser cutters are the snipers of the construction world, hitting the bullseye every time.

Material Mastery: From metals to plastics, they’re the Jack-of-all-trades, adapting to whatever your project throws at them.

Flash-like Speed: Need it done yesterday? Laser cutters are speed demons in the workshop, ensuring your deadlines are met.

Now, onto the limitations – every hero has their kryptonite, right?

Material Matters: While laser cutting machines are versatile, some materials can be a bit stubborn. Reflective surfaces, in particular, can throw a wrench into the works.

Thickness Troubles: Thicker materials might slow down your laser cutter’s groove. Know the limits and play within them.

Alright, let’s get tactical. Planning and executing laser-cutting projects is like preparing for a mission – you need a game plan with some finesse.

Material Tango: Dance with your materials. Different materials require different settings, so play around with what you have and get cosy with the specs. If you’re facing a material you’ve never worked with before, consider leaving it to the experts at Lightning Laser.

Design Like a Boss: The digital canvas is your playground. Spend some time crafting a design that’s not just good but downright legendary. The more time you spend on the design itself, the better the results will be.

Calibration Station: Regularly calibrate your laser cutter. It’s like giving it a pep talk before the big game. If you don’t own your own laser cutting machine, contact Lightning Laser to execute your next precision job.

Safety First, Last, Always: Goggles on, folks! Safety is a must, but even more so when you’re working with lasers. A secure workspace is the secret sauce to a smooth operation. The experts at Lightning Laser swear by protective eyewear and safety gloves.

You’ve got the basics down; now, let’s talk about taking it up a notch. How do you make your laser cutting machine sing like Sinatra?

Master your machine’s settings. Adjust power, speed, and frequency to match your task.

Treat your laser cutter like a prized possession. Regular cleaning and check-ups ensure it stays in tip-top shape, delivering top-tier quality.

Don’t be afraid to sacrifice some scraps to increase your skillset. Every cut is a lesson, and every lesson makes you a laser maestro.

Now, if all of that sounds a bit beyond the scope of your skillset, it’s time to turn to the experts. Laser cutting is a specialised process, but the team at Lightning Laser can take your design and your preferred material and make your vision come to life.

You can come to Lightning Laser to get laser cut wood, timber and metal signs, as well as laser cut corten steel signs, stainless steel signs and aluminium signs. We also work with plexiglass, corrugated plastic, acrylic and rubber. Even better? We offer complementary anodising and galvanising services to protect aluminium, iron and steel signage from corrosion.

Beyond laser cutting machines, Lightning Laser offers all sorts of services that will go hand in hand with your laser cut project. Offering sheet metal bending at architectural standards, we have multiple types of metal fabrication on offer to suit your needs. Once it’s been cut to precision, we can galvanise, anodise or powder coat that metal for you too.

Unlock a whole new world of precision when you use Lightning Laser Cutting for your next engineering or construction project. Whether you need laser signage in Melbourne or need an expert with a laser cutting machine to cut metal to your specifications, make us your first port of call. Contact us today for a quote!