Whether you’re looking for that unique gift to make someone’s year or a bespoke piece of signage to set your shop apart from the competition, a wood laser cutter could be just the thing you need. So, what will you be making?

When it comes to wood laser cutting, the sky’s the limit on what you can do really. But if you need some starting points, we’ve got you sorted.

Wood signage instantly conveys a sense of elegance and familiarity. From cosy cottage vibes to harkening back to days-gone-by, wooden signage can entice customers into your shop and bring them over to your booth with a smile on their faces already.

Make those precious memories even more special with a custom frame. This could link back to the photo or simply match the rest of your decor perfectly.

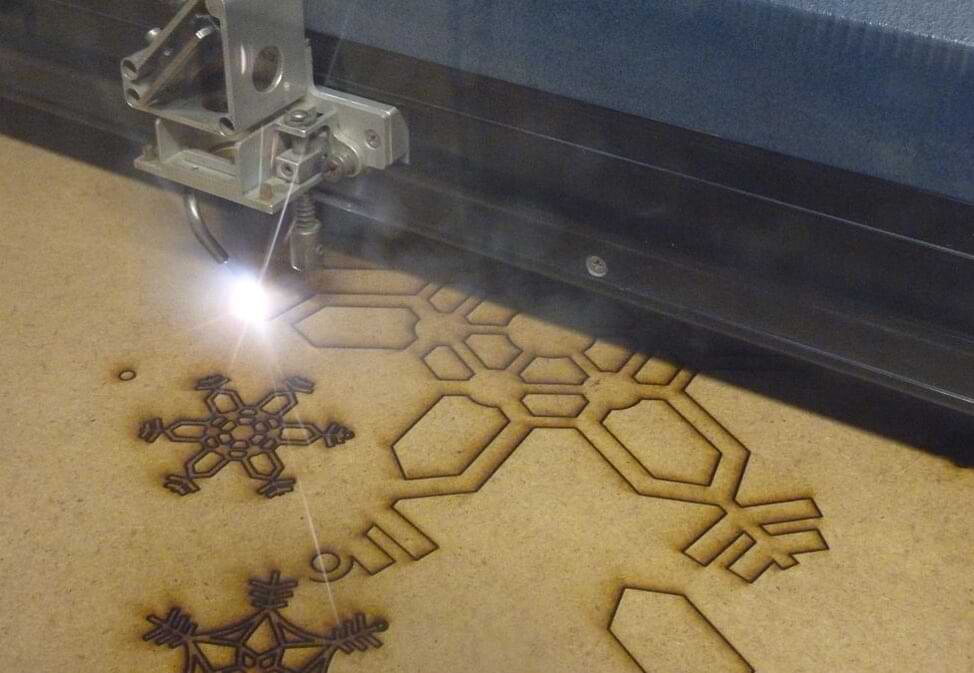

Thanks to the intricate details you can create with laser cutting, this makes it the perfect option to create something delicate or detailed. This can be a way to up cycle existing furniture or complement your own carpentry skills with a signature touch.

Whether it’s for your wedding or just to tell someone you’re thinking of them, you can create beautiful keepsakes, including key chains, with a wood laser cutter. Add some engraving to complete the piece too.

If you’ve ever scoured the stores, both physical and online, for just the perfect thing and come up empty-handed, a wood laser cutter could be your salvation. For instance, create the perfect place to store tools, jars or even clothes with a custom-made frame or box, perfectly cut to size and even cleverly slotted together with the power of laser cutting!

Before you get cutting, take a moment to digest these handy tips to ensure it’s smooth sailing from start to finish.

The wood you choose to work with needs to be right for laser cutting. First and foremost, you want to choose a wood with a lower sap or resin content. This helps to minimise edge burning when the laser cuts through it.

In the realm of softwoods and hardwoods, you’ve got plenty of great options from pine through to mahogany. You shouldn’t have much of a problem working with any soft or hardwoods, it’s more a case of how easy that wood is to find and how expensive it will be. Generally, you’ll find softwoods, like birch or pine, are more abundant and therefore cheaper. If you do end up using a softwood though, remember to treat it for weather resistance if you intend to use the finished product outside.

But can all wood be laser cut? Well, when you’re shopping around for wood, it’s important to steer clear of MDF and other fiberboard. The way these woods are made often means they don’t cut as cleanly, leading to more edge burning.

In the interests of health and safety, it’s also best to work with wood that has had as little processing or treatment as possible. This includes stains, paints and glues which can be vaporised by the laser, turning into harmful fumes. Once the wood is cut, you can then apply these treatments.

No matter your end goal or your design, it’s good to create a few prototypes to be sure you’ll be happy with the end result. These don’t have to be made of wood either! For instance, if you’re looking to make a unique frame for a favourite photo, create your design using cardboard and scissors or a craft knife to see if you like the look of it. For furniture inlays, a paper cutout might help you to get a sense of what your end design will look like.

Prototypes help ensure that when it does come time to cut your wood, you won’t suddenly realise there’s large-scale issues with your design. Instead, you’ll be confident that you’ll like the end product. This helps save you time and money, as well as heartache.

Why just cut wood when you can also engrave it? This can help give your design another layer of depth, as well as plenty more opportunities to personalise your finished product. For instance, if you’re making keepsakes for guests at your wedding, you can engrave their names into their individual mementos and have them double as place settings.

Investing in a wood laser cutter is an expensive process; not to mention the learning time to become an expert craftsman. However, you can skip all that when you have a chat with the team at Lightning Laser. Our experienced technicians are ready to help you create something truly unique and outstanding with laser cutting and engraving options.

And we don’t just cut wood; our facilities include specialist acrylic and metal laser cutters to ensure you get just the result you’re after. So, get in touch today to get the ball rolling.