Manufacturing of goods of any kind is a tricky and complex procedure, and often uses a variety of parts. When it comes to sheet goods like metals, plastic, wood and even cloth, using technology like laser cutting and plasma cutting makes it easy to accurately cut materials to the right shape and size. While there are some similarities between the two, there are also some key differences you should consider when choosing between a laser cutting service or a plasma cutting one. Read on to understand the best choice for yourself.

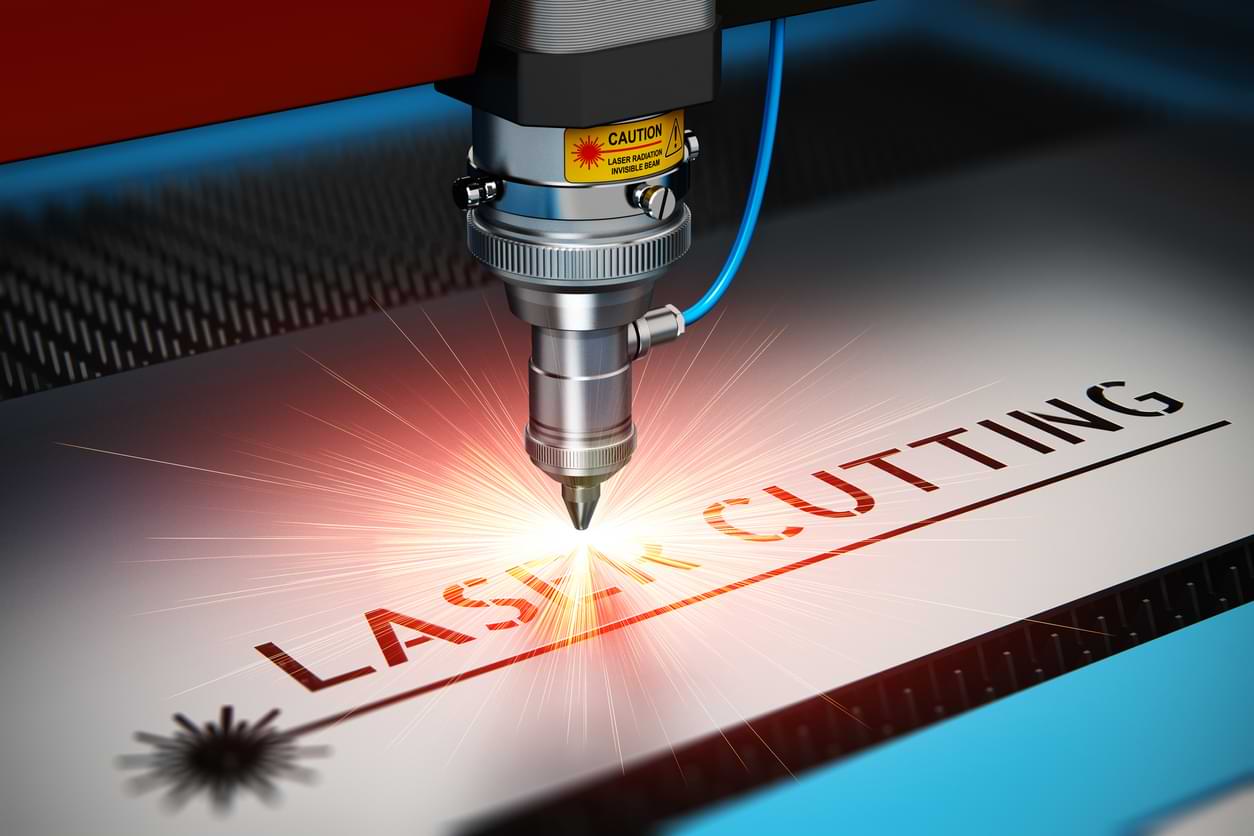

In the laser cutting process, an intense beam of photons is aligned and fired at a specific wavelength, along with a jet of a high-pressure gas, such as nitrogen. While the beam helps vaporise, melt and cut through the surface of the material, the gas shields the material, and blows away any fine filings, also known as swarf.

Laser cutting is useful in all kinds of applications and scenarios, from industrial uses to more artistic uses, like etchings. It is also a versatile process, as you can laser cut steel, other metals and alloys, and even textiles, based on your requirements.

Laser cutting’s origins date back to the 1960s, and it is one of the newer technologies in the manufacturing space. It is still evolving and getting better as more advances are made, and is an important step in the manufacturing process for many goods and products. To gauge whether you should opt for a laser cutting service, you should understand its pros and cons.

Plasma cutting is similar to welding in the sense that it uses an electric arc with superheated, electrically ionised gas (plasma) to direct the jet and make cuts on the metal. As electricity travels down the plasma stream, it generates sufficient heat to melt and cut through the metal. Temperatures can go as high as 20,000°C, but a shielding gas like argon or nitrogen, or compressed air is used to blow the molten metal away, which results in the separation of the workpiece.

Plasma cutting is one of the oldest cutting methods used across industries and was introduced in the 1950s. While it is more limited in its scope and application than other options, such as lasers, it is still an effective and appropriate process in some cases. To understand whether plasma cutting is the best option for you, look at the pros and cons below.

Choosing between laser cutting and plasma cutting comes down to your needs, and the material you are working with. Plasma cutters are the better option for thicker metals, and the highly reflective ones. They are also often cheaper to operate. That being said, lasers are catching up, and some can be used with reflective metals as well.

Laser cutting services also cater to a wider range of applications, may it be in terms of the actual process itself (like cutting, etching, carving), or the material used, as explained earlier. Barring some specific cases and requirements, laser cutting should generally be the better option for you, which is also underscored by the fact that it is much more precise and not as harmful to the environment.

If you are on the lookout for Melbourne-based laser cutting services, look no further than Lightning Laser.

At Lightning Laser, we understand the process of laser cutting inside-out, and have decades of experience in it, and other related services. Our cutting-edge technology and computerised laser cutters provide a quick and seamless finish with a negligible margin of error at a cost-effective price for all our customers. If you have any questions about our services, or simply need more details, send us an email at [email protected], or call us at (03) 9587 7999 to speak to one of our friendly team members.