When many people think of laser cutting, their mind may drift to old spy films such as James Bond, in which the hero desperately attempts to escape their bonds before the laser hits. Simply put, laser cutting is the process of slicing through a material via the use of a laser beam. Whether you are looking to trim a material down, to cut out an intricate outline, or to pull off a cut that cannot be done with conventional drills, laser cutters are invaluable.

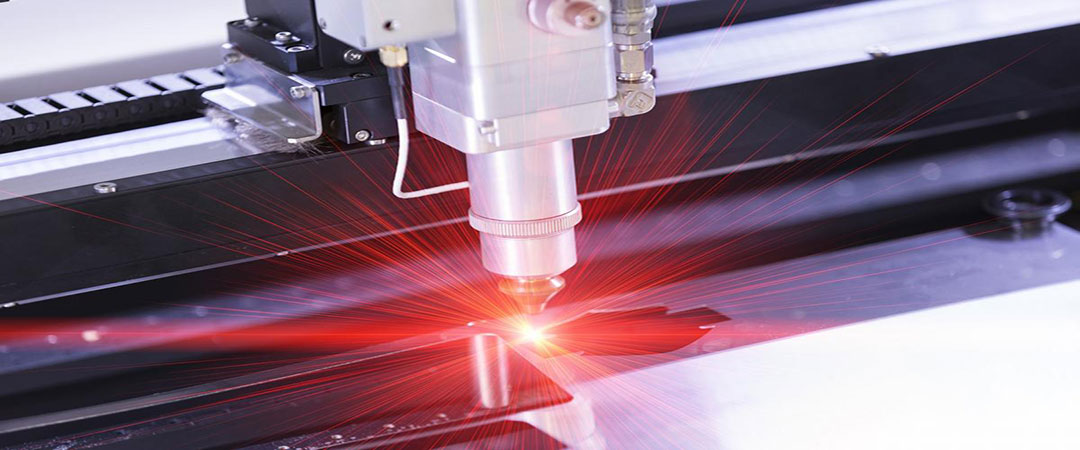

Laser cutters are able to deliver a clean and accurate cut by focusing a laser beam on an object and having it run through the given material. The heat and precision of the laser melt away any material in its path, although to the naked eye the process looks more like cutting. The process of laser cutting can be used on a wide range of material, ranging from soft cloths up to some of the toughest on Earth.

A laser cutter operator can control a number of things to provide the best quality cut for the job, including the intensity of the laser, the length, and the heat output. Different materials will require different levels of heat to cut through without leaving damage to the desired parts. A mirror or special lens can also be used to focus the beam even further if needed. The laser cutting process is so accurate that it can carve slits as narrow as 0.1 millimetres. This makes the process ideal for intricate jobs that simply cannot be achieved by hand, or even other drilling/cutting equipment.

Laser cutters can be used to cut, mark, drill, and engrave a number of different common materials. This is one of the major advantages of the laser cutting process, as the equipment is very versatile across different materials. It should be noted that different materials may require different settings on the laser cutter. For example, something soft like a loaf of bread will not require the same heat settings as something tougher like stone or metal. It is also important to know that, although laser cutters can cut through some materials, they will only be able to cut through a certain thickness of tougher material.

Laser cutters can be used for a range of different jobs and are not limited to simple slice and dice jobs. Lasers can be used for cutting, engraving, marking, drilling, and more.

There is a multitude of different options when it comes to choosing software for your laser cutter, which each specialising in different areas. You must first consider what you are going to be using your laser cutter for, and what functions you need for it to be able to carry out. Are you looking to perform simple cuts? Are you looking to cut out intricate designs? Do you want to be able to engrave text? Perhaps you want to mark an image onto a certain material? The laser system software is readily available, you just need to shop around and find what is best for you.

There are three main types of laser cutter on the market, all of which produce the use the lasers slightly differently, as well as being able to cut through different types of material. The type of laser determines what it can penetrate, with more high-powered versions being ideally suited for metal, while low-powered versions can cut through things such as paper and wood.

> Gas laser – A gas laser, also known as a CO2 laser, uses electrically stimulated carbon dioxide, produced within a mixture of other gases such as nitrogen and helium, to cut through material. This type of cutter boasts the power to slice through thicker material with a 10.6 mm wavelength laser. For use with thicker materials, a gas laser will give you a smoother finish. Gas lasers are the most common on the market. They are cheap, efficient, and can be used to cut through wood, acrylic, paper, leather, glass, and some plastics and foams.

> Crystal laser – In technical terms, crystal laser cutters use beams created from neodymium-doped yttrium ortho-vanadate and neodymium-doped yttrium aluminum garnet. These cutters have a higher intensity than gas lasers, meaning they can cut through thicker/stronger material. However, the higher power does mean that parts have to be replaced more often. These lasers can cut through plastic, metal, and even some ceramic.

> Fiber laser – The beam within these cutters comes from a seed laser, before it is amplified by specialised fibers. Fiber lasers are more energy efficient than gas lasers, and can even cut reflective materials. They can be used to cut plastics and metals. Fiber lasers are a cheaper alternative to crystal lasers as they last longer.

As well as the type of laser, there are also three main types of machine configuration for a laser cutter. These are moving material, hybrid, and flying optics. The configurations differ in the way that the laser is moved across the material it is cutting.

For the very best laser cutting services in Melbourne, contact Lightning Laser Cutting, the home of the world’s finest and most efficient cutting equipment on the market. The dedicated team at Lightning Laser have decades of experience covering laser cutting, designing, engraving, marking, powder coating, anodising, and more. This makes Lightning Laser your one-stop-shop for all things related to laser cutting.

The team pride themselves on being transparent with all clients from the very first meeting until the last, walking customers through the process from start to finish. While Lightning Laser specialises in metal cutting, they are also extremely qualified and experience in a range of other materials. They guarantee the accuracy of 0.1mm, reduced set-up times, on-time delivery, affordable prices, and high-quality results.

Lightning Laser is not only widely regarded as one of the best in the Melbourne area in the laser cutting sector, but one of the best in the world. Laser cutting is not only a job for this company, but it is also their passion. A huge slice of the Lightning Laser profits goes back into purchasing the latest machinery and equipment to maintain the high standards they set for themselves.

This guarantees accuracy, precision, and an on-time delivery for you, the customer. Not only this, but Lightning Laser are happy for you to be a part of the process every step of the way, from sending in your design to giving feedback on the final delivery. Contact the team at Lightning Laser today for all of your laser cutting needs.